Industrial Vee Belt

If you want to install easy, handy and low load belt, than Vee belt gives you compactness due to the small distance between the centres of pulleys. The drive is positive because the slip between the belt and the pulley groove is negligible. Since the V-belts are made endlessly and there is no joint trouble, therefore the drive is smooth.

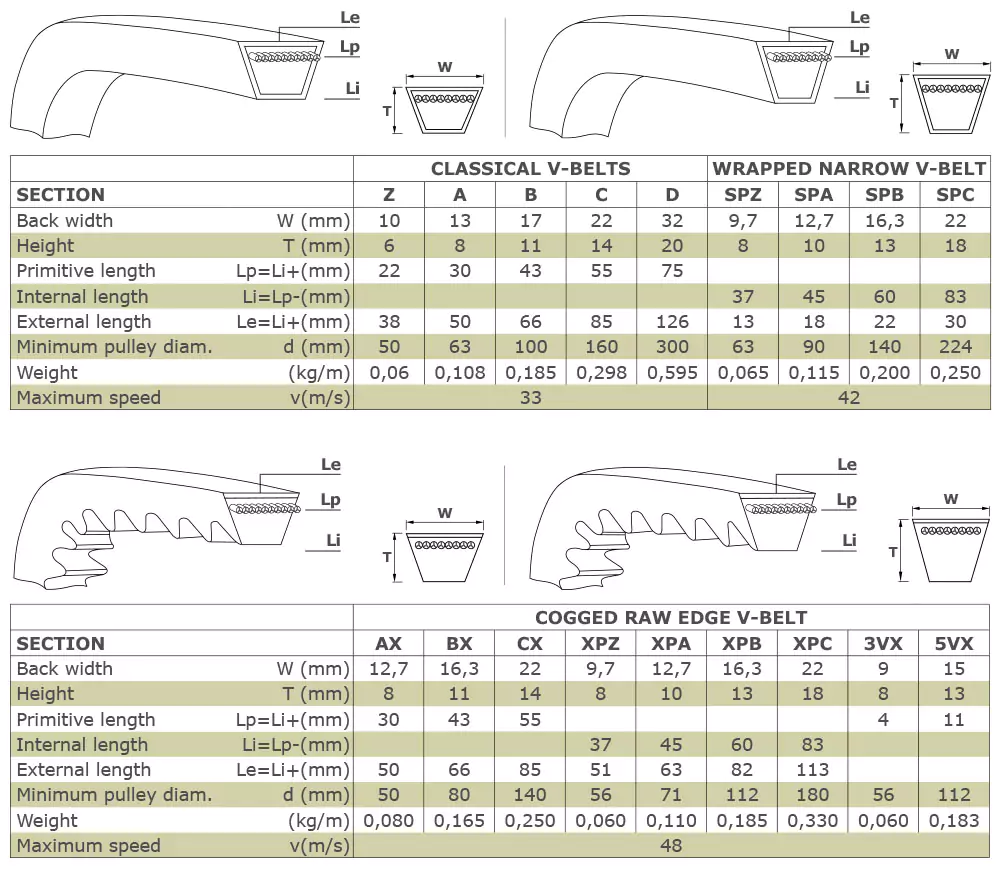

V-belts are used to transmit mechanical power efficiently between different parts of a machine. V-belts can also be categorized according to the cross-section. The most common cross-sections are standard, wedge, narrow, fractional horsepower, banded, cogged, and double. See below detail.

CLASSICAL AND NARROW V-BELTS

are an excellent solution for a wide range of drives. Classical V-belts are available in Z,A,B,C and D section, whereas Narrow V-belts in SPZ, SPA, SPB and SPC section. In both cases belts are wrapped with a textile cover. It assures maximum protection against heat, oil and ozone.

COGGED RAW EDGE V-BELTS

replace traditional V-belts in demanding drive systems where space and weight reduction is crucial. Superior design delivers maximum power and high speed – even in pulleys with very small diameter. They are available in AX, BX, CX, XPZ, XPA, XPB, XPC, 3VX and 5VX section.

Thanks to a unique production cycle (according to UNISET technology) we are able to secure limited and constant tolerance of these belts. The precise dimensions of this product fits perfectly in applications of the industrial and agricultural market.

PROPERTIES:

- Low-stretch cords – extended lifetime & great performance

- Wrapping – maximum cover against heat, oil, ozone

- UNISET technology – dimensional stability guarantee

- Temperature range: -20°C ~+70°C (-25°C ~ + 80°C for cogged belts)